Innovation and Technology

- Modular Integrated Construction (MiC)

- Rectangular Tunnel Boring Machines (RTBM)

- Internet of Thing (IoT) Sensors and Tools

- Eco-shoreline

- Non-dredged Reclamation Technology - Deep Cement Mixing (DCM)

- CEDD Innovation and Technology Seminar 2021

- CEDD 'n I Week

Modular Integrated Construction (MiC)

MiC, one of the off-site construction methods, refers to the construction of free-standing integrated modules (completed with finishes, fixtures and fittings) manufactured and assembled in a factory and then transported to site for installation.

It makes use of the concept of "factory assembly followed by on-site installation" and on-site construction processes are transferred to the controlled factory environment. This not only improves productivity, quality control, site safety and sustainability but also reduces the adverse impacts of inclement weather, shortage of labour, etc.

Provision of Temporary Quarantine Camp at Penny's Bay

The scope of contracts includes design and construction of temporary quarantine camp, comprising 100 and 300 quarantine units in Phase IA and Phase IV of the camp respectively using MiC alongside site formation, infrastructure and ancillary works.

The components of each MiC unit including structural steel frame, concrete floor slab, fire resistant board, partition wall, ceiling, internal finishes, exterior wall cladding, door, window, toilet seat, washing basin, cable conduit, lighting, power socket outlet, etc. were installed in the fabrication yard in Mainland China prior to delivery on site.

Rectangular Tunnel Boring Machines (RTBM)

Tunnel Boring Machine (TBM) is a machine, equipped with rotating steel cutter heads at the front, used to excavate tunnels cutting through soil and rock strata. The most commonly used TBM in the construction industry is circular in cross section.

Under Kai Tak Development (KTD) – Stage 3B Infrastructure at Former North Apron Area, a pedestrian subway SW4 of about 180m is constructed across Prince Edward Road East, Kwun Tong Bypass and Shing Kai Road connecting Choi Hung Estate and KTD.

A rectangular TBM (RTBM) with dimensions 5m(W) x 4m(H), for the first time in Hong Kong, is deployed for the construction of the pedestrian subway to enhance site safety, reduce construction risks, raise quality of works and minimize the disposal of excavated materials.

The subway is located approximately 10-12m below ground level and is installed by the progressive jacking of 1.5m long rectangular precast tunnel segments immediately after each drilling operation of the earth pressure balanced RTBM.

Internet of Thing (IoT) Sensors and Tools

Conventionally, scheduled inspections and receipt of emergency call are replied upon for carrying out necessary maintenance of facilities located in remote areas. By adopting the technologies of IoT sensors and tools, inspection and maintenance personnel will receive instant notification when abnormal conditions are detected, such that prompt actions can be carried out.

Sensor-based Monitoring System for Marine Facilities

There are over 320 piers and landings and about 130 km of breakwaters and seawalls in Hong Kong being maintained by the Port Works Division of the Civil Engineering and Development Department (CEDD). It is essential to maintain the marine assets in satisfactory condition against adverse effects of coastal hazards. Due to its geographical location, Hong Kong is vulnerable to the threat of tropical cyclones. Coupled with the impact of climate change, extreme weather conditions are expected to become more frequent. Therefore, it is particularly important to strengthen the inspection and maintenance of marine facilities.

CEDD has developed a Sensor-Based Monitoring System for piers, breakwaters and seawalls to collect real-time data on the impact force and vibration caused by vessels on piers when berthing, and the movement of armour rocks of the breakwaters and seawalls due to waves and tidal action in order to more effectively assess the structural integrity of the above-mentioned marine facilities.

Vessels will have impact forces on the piers during berthing. If the impact force exceeds the allowable berthing load of a pier, it may damage the pier. The above-mentioned sensing system can continuously collect data through sensors such as vibration sensors and satellite positioning system, and upload it to the central processing system for automatic real-time data analysis. If the impact force exceeds the set value, the system can immediately send out message to notify relevant maintenance engineers to inspect and repair the relevant marine facilities as soon as possible.

This System helps us in monitoring the structural health of piers and allows us to have more speedy response to any defects identified in piers, and also facilitates the formulation of long-term maintenance strategy. "Sensor-based Monitoring System for Piers" invented by Port Works Division received a Bronze Medal in the 2023 Geneva International Exhibition of Inventions (Chinese only)

Related Links

"Sensor-based Monitoring System for Piers" invented by Port Works Division received a Bronze Medal in the 2023 Geneva International Exhibition of Inventions (Chinese only)

Smart Barrier System

The Government has been constructing barriers at natural stream courses and hillsides to intercept landslide debris, thus reducing the chance of casualties caused by debris impacting on downhill buildings and facilities. The Smart Barrier System applies novel Internet-of-thing (IoT) technologies for all-weather and non-stop monitoring of the barriers. When the barrier is hit by landslide debris, the system will immediately alert our geotechnical engineer. This enables timely inspections and follow-up actions to safeguard the public.

The first prototype of the Smart Barrier System was designed and installed at a barrier for field trial in 2017. The system comprises impact switches for detecting debris impact, depth gauges for measuring thickness of debris accumulated behind the barriers, cameras for monitoring the field conditions and screening out false alarms, etc. Depth gauge measurements and camera images taken at regular intervals are stored in cloud server via mobile networks. GEO uses a dedicated mobile application to facilitate the real-time monitoring of conditions of the barriers.

Some smart barriers are located at areas not covered by power supply networks or mobile networks. As an alternative, the system adopts IoT devices with low power consumption accompanied by self-contained power supplies, e.g. solar power. In addition, low-power wide-area networks such as Narrowband-IoT and LoRa are used for connecting and transmitting data to the cloud server. CEDD has engaged more suppliers to provide prototype designs for field trials with a view to enhancing and continuously improving the reliability and performance of the Smart Barrier System.

Eco-shoreline

Eco-shoreline, a new concept in Hong Kong, is introduced to artificial seawalls at different types of water bodies on trial to sustain both human activities and marine biodiversity. There are many types of eco-shoreline features including enhanced seawall panels, ecological armouring units, tidal pools and oyster baskets, etc.

Site Trials

CEDD, is working in partnership with the University of Hong Kong, installed some eco-shoreline features as site trials at the seawalls in Sai Kung, Tuen Mun and Shatin progressively from March to October 2019 to investigate the effectiveness of adopting eco-shoreline to enhance marine ecology and biodiversity on artificial shoreline. The selected trial locations for this study at Sai Kung, Shatin (Tolo Harbour) and Tuen Mun are identified as oceanic, semi-enclosed and estuarine types of water bodies respectively. Such arrangement helps assess the feasibility of application and development of eco-shorelines in different types of water bodies in Hong Kong.

Site installation of eco-shoreline features and monitoring were completed in December 2021. As evaluated by the study, overall, a higher number of species and more diverse communities were consistently encountered in eco-shoreline features (i.e., for mean species richness and percentage coverage) when compared to the controls. Eco-shoreline features thereby transforms the artificial seawalls at the trial sites into "living" seawalls.

With solid scientific evidence established and experience gained, the concept of eco-shoreline has been further applied to the existing seawalls at Tsuen Wan, Causeway Bay, Wan Chai and West Kowloon Cultural District. It is striving for further apply eco-shoreline in various projects, i.e. existing artificial shoreline, upcoming reclamation projects, coastal enhancement works and pier improvement projects.

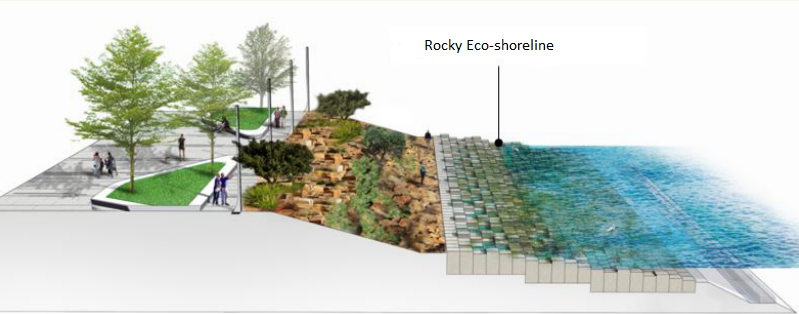

Adoption of Eco-shoreline at Tung Chung East New Town Extension

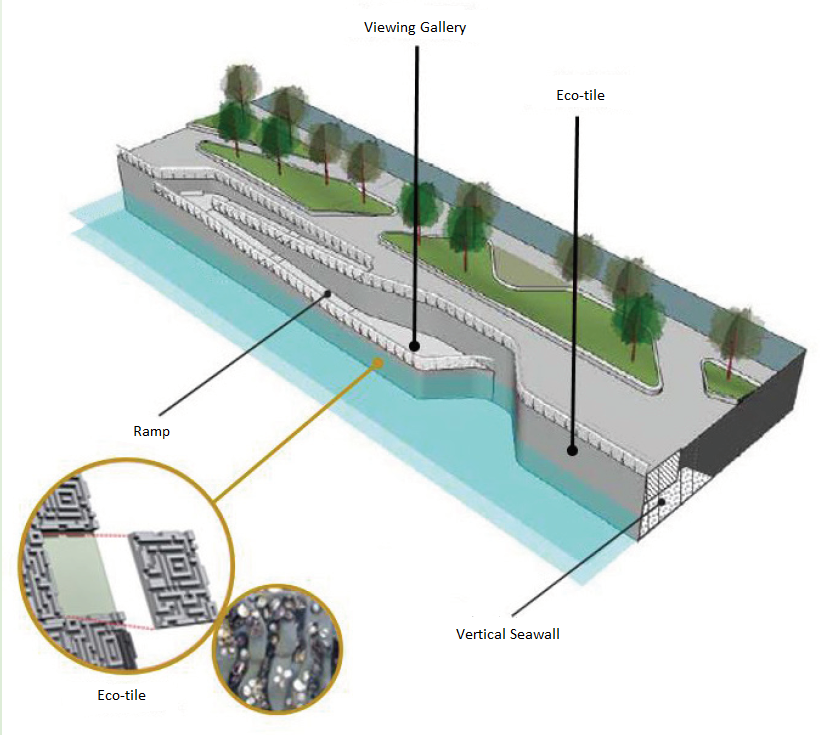

Tung Chung East New Town Extension project is the first public works project adopting eco-shoreline, with the primary objective of mimicking the natural inter-tidal zones as far as practicable, in a bid to provide a more suitable habitat, namely a tidal eco-system, for colonisation of marine species. Eco-shoreline will be provided on the new slopping seawall and vertical seawall.

Mangrove eco-shoreline and rocky eco-shorelines would be provided to suit the condition of different sections of slopping seawall, such as susceptibility of the shoreline to sea waves and abundance of sunlight, so as to provide a suitable habitat for marine species to enhance the bio-diversity on the seabed.

Cavity and pots will be installed at suitable positions on the vertical seawall to form a sheltered environment and habitat for marine life and plants. The surface of the vertical seawall will also be equipped with eco-tiles, and its uneven surface can make it easier for smaller creatures to grow on it. In addition, viewing galleries will also be provided to facilitate the public's close observation of marine lives on eco-tiles, showcasing the marine ecology by means of "outdoor classrooms" to promote a water-friendly culture in an interactive manner.

Non-dredged Reclamation Technology - Deep Cement Mixing (DCM)

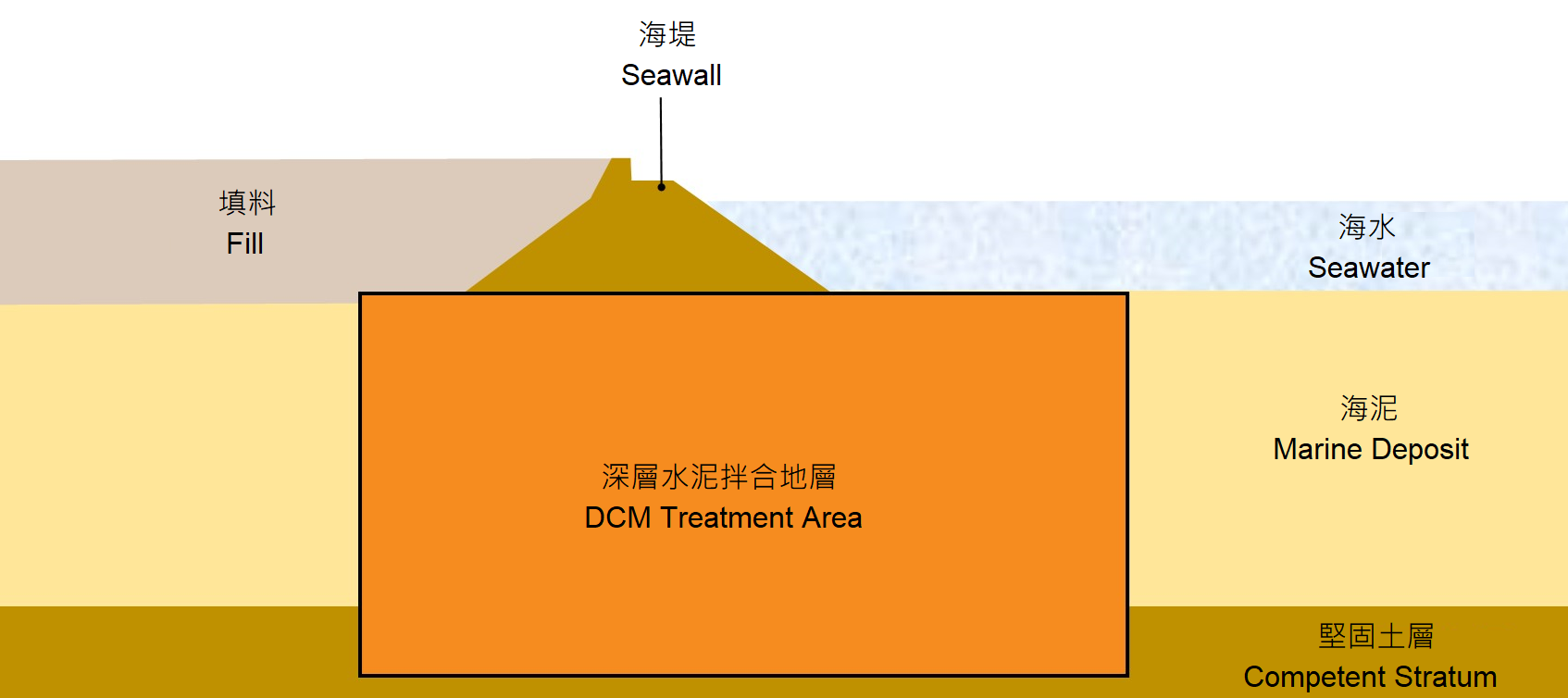

Traditionally, it is required to remove soft marine deposit by dredging for the construction of seawall. However, this dredged method may induce environmental impact to the waterbodies nearby and lead to disposal issues of the dredged materials. With a view to mitigating the environmental impact, we adopt non-dredged reclamation method.

Tung Chung New Town Extension - Reclamation and Advance Works

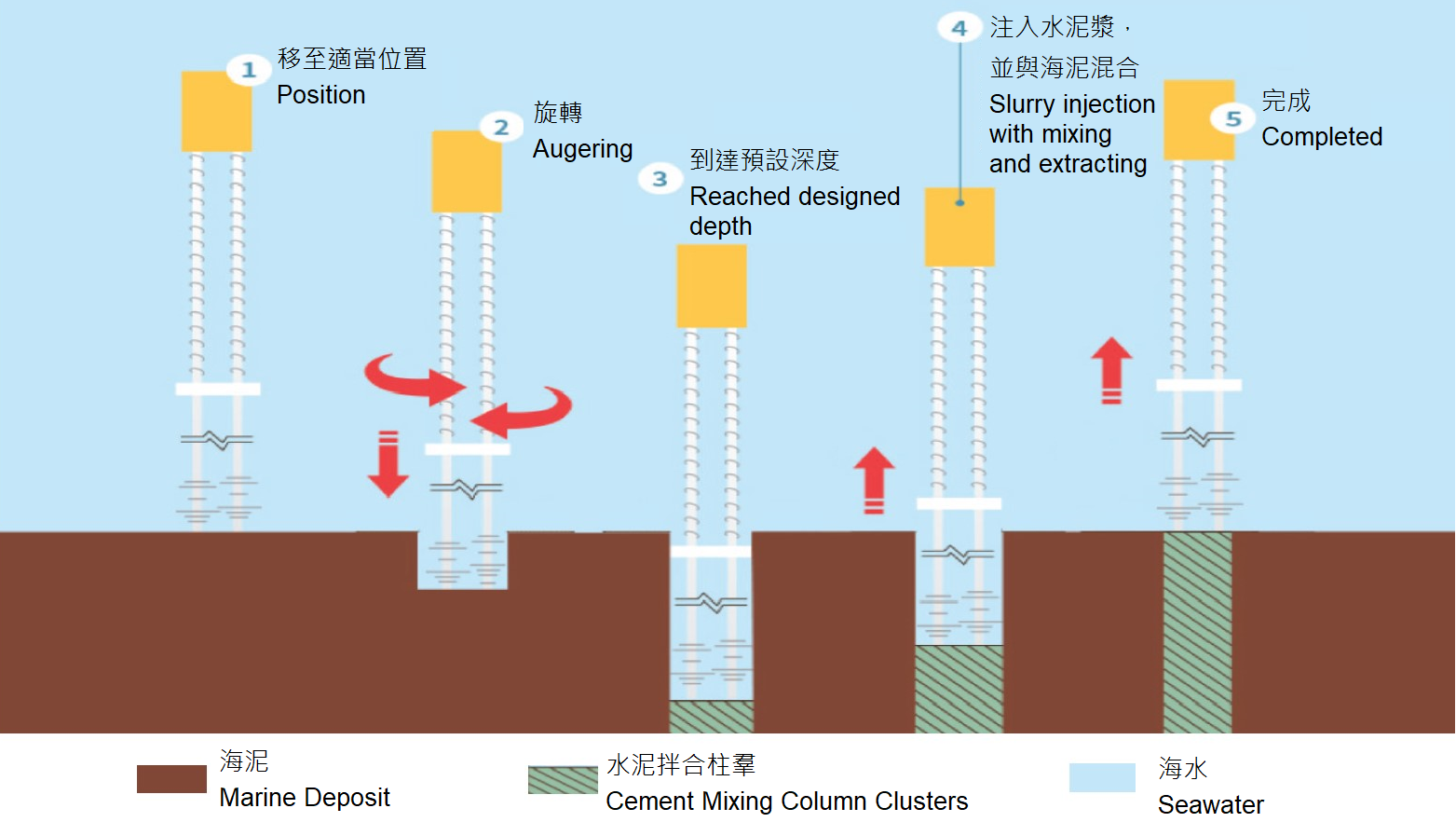

The Tung Chung East reclamation contract adopts non-dredged method for reclamation and construction of seawalls. A new technology DCM method has been adopted to strengthen the soft marine deposit to enhance the stability of the seawall foundation.

The principle of DCM is to inject cement slurry into the marine deposit and mix them mechanically to form a cement mixing column. These cement mixing column clusters will form a DCM treatment area, to stabilise the seabed underneath before the construction of the seawall and reclamation works. Compared with the traditional dredged reclamation method, DCM does not involve the dredging of sea bed and disposal of the dredged materials, causing less impact to water quality and marine ecology.

It is the first public works project using this technology.